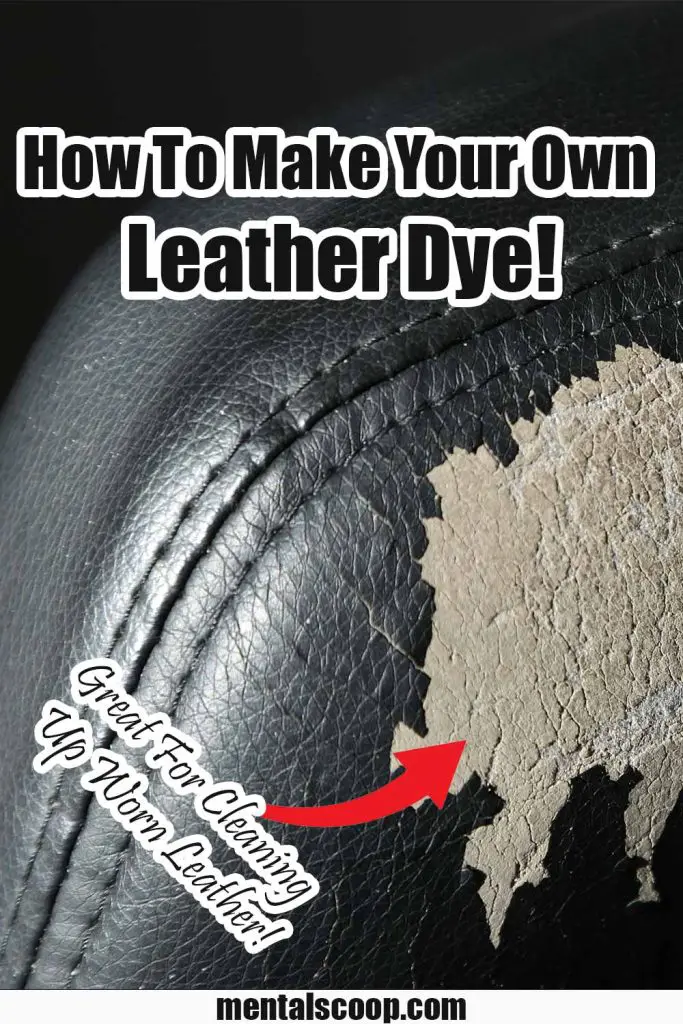

How To Make Your Own Leather Dye, Great For Cleaning Up Worn Leather!

Leather crafting is a captivating art form that allows you to create unique and personalized items. One essential aspect of leatherworking is dyeing, which adds color and character to your creations. While commercial leather dyes are readily available, making your own leather dye can be a rewarding and cost-effective alternative. In this article, we will explore the fascinating process of creating your own leather dye using natural ingredients. Let’s dive in and unleash your creativity!

Understanding Leather Dyeing Before we delve into the process of making your own leather dye

It is crucial to understand the basics of leather dyeing. Leather dye is a coloring agent that penetrates the leather’s surface, bonding with the fibers to create a lasting color. The dyeing process involves three primary steps: preparing the leather, applying the dye, and finishing with a protective sealant. By making your own leather dye, you have greater control over the color intensity, tone, and the materials used.

Gathering the Necessary Materials To begin your leather dye-making adventure, gather the following materials:

- Natural colorants: Explore natural sources such as plants, fruits, vegetables, and tree barks. Some popular options include onion skins, black walnuts, avocado pits, and madder root.

- Distilled water: It is essential to use distilled water to avoid impurities that may affect the dye’s quality.

- Mordants: Mordants enhance colorfastness and help the dye adhere to the leather. Common mordants include alum, vinegar, and salt.

- Glass or stainless steel containers: These containers will be used for mixing and storing your homemade dye.

- Heat source: A stove or hot plate will be necessary for heating the dye mixture.

- Straining materials: Use cheesecloth or fine mesh strainers to remove any solid particles from the dye solution.

- Measuring tools: Accurate measurements are crucial, so have measuring cups, spoons, or scales on hand.

- Protective equipment: Gloves, apron, and safety goggles will help ensure your safety during the dye-making process.

Creating Your Leather Dye Now, let’s explore the step-by-step process of making your own leather dye:

Step 1: Preparing the Natural Colorants Choose your desired natural colorant(s) and prepare them accordingly. For example, if using onion skins, collect a sufficient amount and boil them in water until a deep color is achieved. Strain the liquid and set it aside.

Step 2: Determining the Dye Concentration Decide on the desired dye concentration based on your project’s requirements. For a stronger color, increase the amount of colorant; for a lighter shade, dilute the dye mixture with water.

Step 3: Creating the Dye Solution In a glass or stainless steel container, combine the desired amount of natural colorant with distilled water. Use approximately one part colorant to three parts water as a starting point. Stir well to ensure the colorant dissolves completely. This mixture forms your dye concentrate.

Step 4: Adding Mordants To enhance colorfastness and improve dye penetration, add mordants to your dye solution. The specific mordant and quantity will depend on the colorant used. For example, alum works well with many natural colorants and can be added in small amounts.

Step 5: Testing the Dye Before applying the dye to your leather project, conduct a patch test on a small, inconspicuous area to ensure the desired color is achieved. Adjust the dye concentration or experiment with additional mordants if needed.

Step 6: Applying the Dye Once you are satisfied with the dye’s color, apply it to your leather using a sponge, brush, or spray bottle. Ensure even coverage and work in small sections, allowing the dye to penetrate the leather fibers fully. Apply multiple coats for a more intense color.

Step 7: Drying and Finishing Allow the dyed leather to air dry in a well-ventilated area. Once dry, you can finish the leather by applying a protective sealant, such as a leather finish or wax, to enhance durability and luster. Follow the manufacturer’s instructions for the chosen sealant.

Tips and Precautions While making your own leather dye can be an enjoyable and fulfilling process, keep the following tips and precautions in mind:

Experimentation is key:

Feel free to experiment with different natural colorants, mordants, and concentrations to achieve unique shades and effects.

Safety first:

Always wear protective equipment, such as gloves, aprons, and safety goggles, to prevent skin and eye irritation.

Patch testing:

Test the dye on a small leather sample before applying it to your final project to ensure the desired color and compatibility.

Document your recipes:

Keep a record of the colorant combinations, mordant quantities, and dye concentrations used to replicate successful dye recipes in the future.

Store your dye properly:

Store your homemade dye in airtight glass containers in a cool, dark place to maintain its quality and prevent spoilage.

More interesting articles you may be interested in reading:

How To Remove A Tree Stump Painlessly

10 Vital Home Maintenance Tasks You’ll Regret If You Forget

See How Much Propane Is Left In A Tank With No Gauge

Thanks for reading and be sure to share this info with your friends using the social share buttons below.

Talking about social stuff, consider liking our Facebook page to keep up to date with our articles. Check out our other articles for more mental scoops!